Semiconductor Packaging Solutions

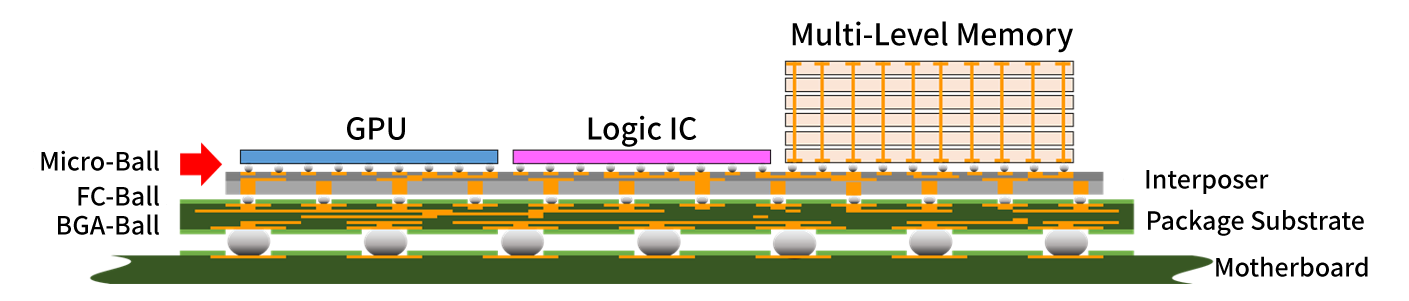

Semiconductor packages have evolved from single-chip FC-BGA, which mounts

one chip on one substrate, to 2.5D SIP (System in Package), which mounts

multiple semiconductor chips on an interposer. The technology for BGA-Ball

(φ150-760μm) and FC-Ball (φ60-90μm) has been established for some time.

The challenge now is to realize Micro-Balls for mounting semiconductor

chips.

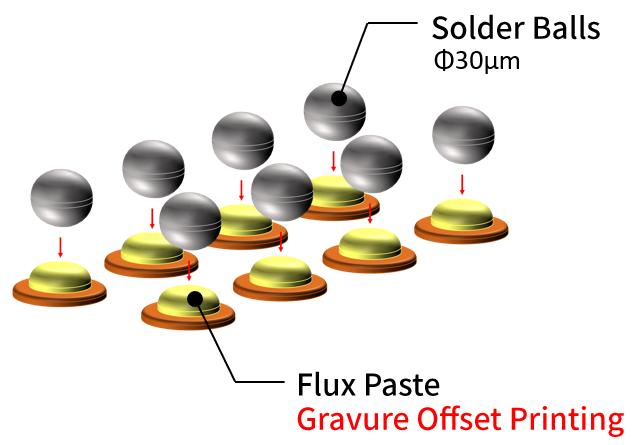

In collaboration with Athlete FA Corporation, a ball mounting machine manufacturer, we have established Micro-Ball mounting technology with a diameter of φ30μm.

In collaboration with Athlete FA Corporation, a ball mounting machine manufacturer, we have established Micro-Ball mounting technology with a diameter of φ30μm.

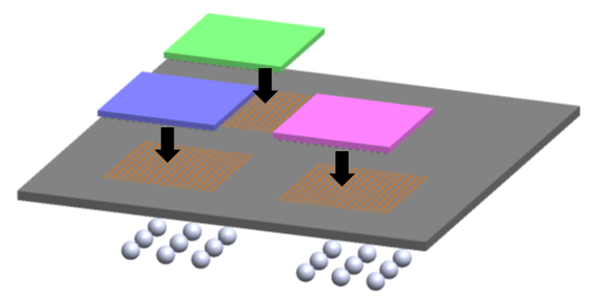

Schematic Diagram of Semiconductor Package (SIP)

System in Package: Mounting multiple chips on an interposer

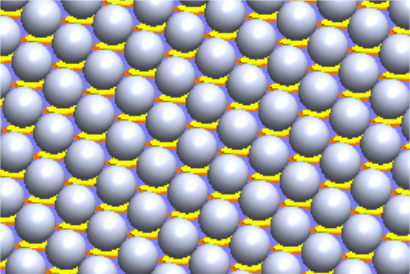

By applying fine printing technology using gravure offset, we print the

flux paste required for mounting solder balls with a high degree of

precision. Gravure offset printing makes it possible to print at a

diameter of 30 μm (pitch 60 μm), exceeding the limits of conventional

screen printing using metal masks.

Electrodes

Print Flux Paste

Mounting Solder Balls

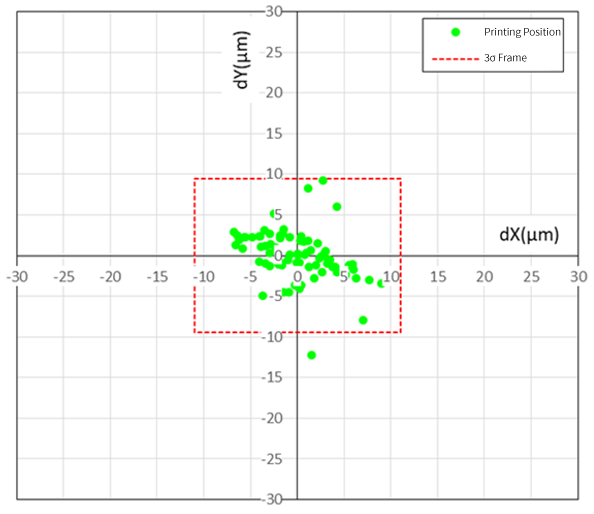

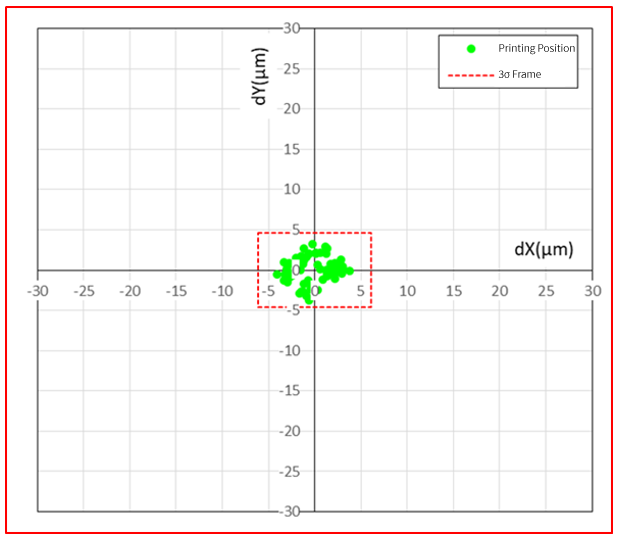

One of the major features of gravure offset printing is its excellent

printing position accuracy. In principle, it is advantageous because it

does not distort the screen mask as in screen printing. Flux paste can be

printed accurately on the electrodes.

Screen Printing

Gravure Offset Printing

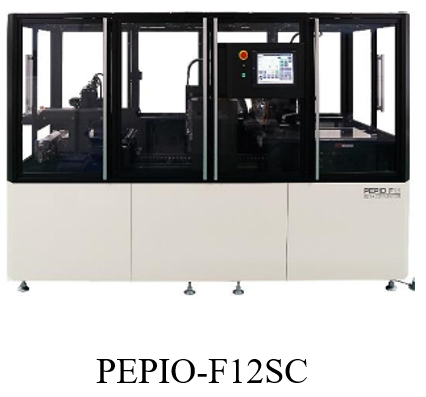

PEPIO-F12SC

BM-1400W

For consultations and requests for materials, please click here

Inquiry

Copyright© 2017-2025 SERIA CORPORATION